The working principle of this methane gas

leak detector is based on a pulsed beam

from a diode laser which is directed at the

location or area to be inspected.

Applications shown:

Marcellus Shale Well Gas Leak Detection

Transmission Line Leak Detection

Equipment:

• 2010 Jeep Wrangler Unlimited Rubicon

• Street Evaluating Laser Methane Assessment "SELMA" Bumper Unit (fixed inspection)

• SELMA Roof Unit (operator directed inspection) | Detection Method:

Our vehicle, equipped with Laser Methane Assessment equipment, is a state-of-the-art mobile methane gas detector that is EPA Method 21 compliant. Its main applications are the detection of methane gas emissions associated with landfills, transport and distributions pipelines, compressor stations, gate stations, gas fired equipment and the identification of unknown sources of methane emissions to the atmosphere. The working principle of this methane gas leak detector is based on a pulsed beam from a diode laser, which is directed at the location or area to be inspected:

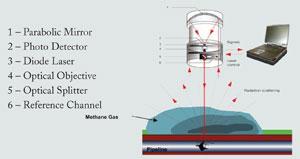

The pulsed beam from the diode laser (3) passes the optical objective (4) and is pointed at the location to be inspected. This laser beam, pointed at the pipeline and/or a leak, is reflected and the scattered reflection is collected by a parabolic (1) mirror. The laser beam passes an optical splitter (5). The main part of the beam goes through but a part of the beam is reflected and goes to the reference channel (6) consisting of a curette with a standardized gas sample. The photo detector (2) generates a signal which is compared to the signal from the reference channel (6).

When the laser beam passes through a methane gas cloud (leak), the laser light will be absorbed and the resulting deformation of the signal is proportional to the concentration of methane along the measuring path. The laser’s wavelength of 1.65 µm corresponds to the first absorption band of methane. The signal generated in this optical unit is processed in the analog/digital card and then analyzed with the gas leak detection software.

A few key advantages of this new methane gas leak detection system are:

• No maintenance

• Remote gas leak detection

• High inspection speed

• Detects only methane

|

Weather:

• Atmospheric Temperature: 60 F

• Relative Humidity: 52%

• Wind Speed: 5 mph (NE)

• Precipitation: None

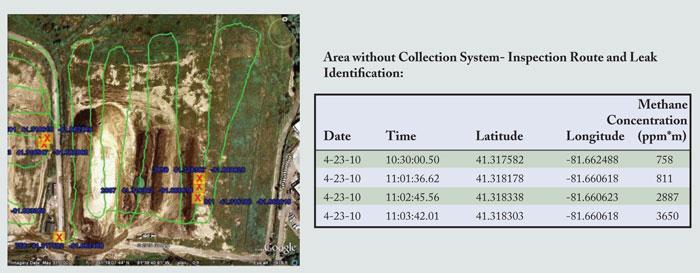

Overall Inspection Route with Leak Identification:

(Above) Green lines indicate inspection pathways. Yellow boxes with Red X’s indicate the locations of methane detections > than 300 PPM. The actual detection levels with geoposition are in Blue.

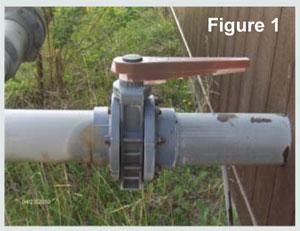

Comments: The detection of 758 PPM was identified as a leak on the Flare Gas Supply System. We further identified and verified the gas leak utilizing a hand held passive infrared camera. The infrared leak video and IR leak report are included as an attachment to this report. The leak is originating from the Gas House Flare Supply Pipe- 6 inch Valve Outlet at Nipple (Figure 1).

The hand held passive infrared camera also identified a leak located on a collection well head (Figure 2) that was not inspected by the mobile due to its location behind the North West corner of the Gas House. An immediate adjustment was made to the vacuum system flow valve which prevented any further loss of methane. Repair to the leaking connection is recommended to prevent the future loss and reduce the amount of ambient air entering the collection system.

The three (3) remaining detections are attributed to an area within and immediately surrounding the area identified by the landfill operator as having a hole in the liner. We recommend the installation of a gas recovery system, cover maintenance and a reinspection of the area.

For a printable file of the above information, click the pdf below

ER Mobile Gas Leak Detection Spec Sheet ER Mobile Gas Leak Detection Spec Sheet

|