Designed for operations/maintenance

personnel to perform frequent valve

checks, Valve-Squeak is an easy-to-

use through-valve loss detection system.

Small enough to fit in your pocket,

Valve-Squeak isolates leaks of any

size and in any valve saving thousands,

if not millions of dollars.

SAVE TIME AND MONEY BY:

• Drastically cutting "sellable" gas losses

• Reducing turnaround time

• Maintaining plant integrity and safety

• Cutting back on maintenance costs

• Moving towards zero emissions

• Meeting EPA Clean Air requirements

• A key tool for LDAR programs

| FIND LOSSES BEFORE THEY GROW

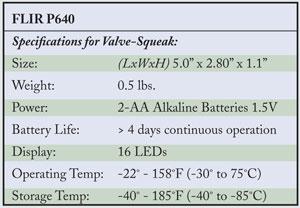

Simple Operation. A green light shows a "no leak" and a yellow LED bar graph shows a leak range of "small" to "very large". Once a leak is identified, your VPAC™ unit can be used for quantification. Valve-Squeak has high noise and vibration immunity and is Intrinsically Safe for use in hazardous, gaseous environments that require Class I, Div 1, IIC, T4 (currently only meeting US certifications).

• The valve leak still needs to be verified and quantified by a VPAC system and operator.

• To keep the Valve-Squeak cost low, it contains simplified electronics.

• With the low cost of the Valve-Squeak it’s possible to have many units in a refinery or plant to help the single VPAC operator locate potential loss.

• VPAC operators are still needed to quantify/measure CFM or GPM.

WHY VALVE-SQUEAK?

• Locates leaks in valves including PSV, RV, CV and all others

• Used worldwide in refineries, chemical plants and offshore platforms

• Realizes plant savings ranging from $500,000 to $5,000,000/year when combined with a VPAC/5131 leak detection system (even leaks in a small valve can result in significant losses)

• ROI is in the first use

• Identifies losses rapidly

• Eliminates excessive flaring

For a printable file of the above information, click the pdf below:

ER Valve Squeak Spec Sheet ER Valve Squeak Spec Sheet

|